TOP > Product > Special Types of Talc

Talc for Food Additives

Food additive talc is manufactured under strict quality management based on the Ministry of Health, Labour and Welfare. The product meets certain standards based on Japanese standard of Food additives.

Talc for pharmacuetical grade

Pharmaceutical grade talc is widely used as glidant and lubricant for coated tablet .

Our sterilized talc is complied with EP, USP and JP.Positive effects

・Fine particle size leads to high coating ablity and less clogging issue in coating process

・Strong anti-tacking properties for pharmaceutical coating that improve manufacturing process

・Excellent cost-performance for increasing the quality of the coated tabletsSpecialty

・Heat sterilization is available with environmentally firendly

・ROSE TALC is registered for Taiwan FDA by DKSH Performance Materials ltd

・Below products are registered in Chinese DMF

・DKSH Performance Materials China Ltd is our exclusive distributor in China of our talc family products, for pharma. excipient application with DMF/CDE registration support.

Our sterilized talc is complied with EP, USP and JP.Positive effects

・Fine particle size leads to high coating ablity and less clogging issue in coating process

・Strong anti-tacking properties for pharmaceutical coating that improve manufacturing process

・Excellent cost-performance for increasing the quality of the coated tabletsSpecialty

・Heat sterilization is available with environmentally firendly

・ROSE TALC is registered for Taiwan FDA by DKSH Performance Materials ltd

・Below products are registered in Chinese DMF

・DKSH Performance Materials China Ltd is our exclusive distributor in China of our talc family products, for pharma. excipient application with DMF/CDE registration support.

| Grade | Whiteness (%) Reflectance | Tapped bulk density (g/ml) JIS K 5101 |

Particle size D50 (μm) Laser diffraction |

Asbestos (%) X-ray diffraction |

|---|---|---|---|---|

| MICRO ACE P-3 | 96 | 0.4 | 5 | Not detected |

| MICRO ACE K-1#90 | 95 | 0.5 | 7 | Not detected |

| TALC MS | 95 | 0.7 | 11 | Not detected |

| ROSE TALC | 94 | 1.0 | 17 | Not detected |

High apparent density talc

High apparent density talc with less oil absorption

is used for cosmetics and paint.

is used for cosmetics and paint.

| Product | Test Item | ||||||

|---|---|---|---|---|---|---|---|

| Whiteness(%) Hunter method |

Particle size D50(μm) Laser diffraction |

45μm residue(%) JIS K5101 |

Moisture content (%) JIS K 5101 |

Apparent density(g/ml) JIS K5101 |

Speciflc surface area(m2/g) BET method |

Oil absorption (ml/100g) JIS K 5101 |

|

| MS-KY | 92 | 21 | 1.0 | 0.1 | 0.55 | 2.5 | 21 |

| MS-T | 83 | 19 | 0.5 | 0.2 | 0.57 | 2.8 | 23 |

Talc for Papermaking

Talc for papermaking is used for internal fillers and pitch control agents made from carefully selected material with low wear resistance to papermaking wires.

| Product | Test Item | Use | ||||

|---|---|---|---|---|---|---|

| Whiteness(%) Hunter method |

Particle size D50(μm) Laser diffraction |

45μm residue(%) JIS K5101 |

Specific surface area (㎡/g) BET method |

Degree of wear(mg) Filcon method |

||

| N-70 | 70 | 13 | 0.5 | 7.0 | 15 | Fillers |

| N-80 | 80 | 13 | 0.5 | 6.0 | 15 | |

| NTP-2 | 80 | 8 | 0.1 | 13 | 15 | Pitch control |

Burnt Talc

Burnt Talc is the pure white talc powder prepared by burning and pulverizing.

It is processed under strict quality control with improved electrical insulation, thermal stability, adhesion, and weather resistance.

Because of the excellent features of the product, it is used in electronic material and related fields.

It is processed under strict quality control with improved electrical insulation, thermal stability, adhesion, and weather resistance.

Because of the excellent features of the product, it is used in electronic material and related fields.

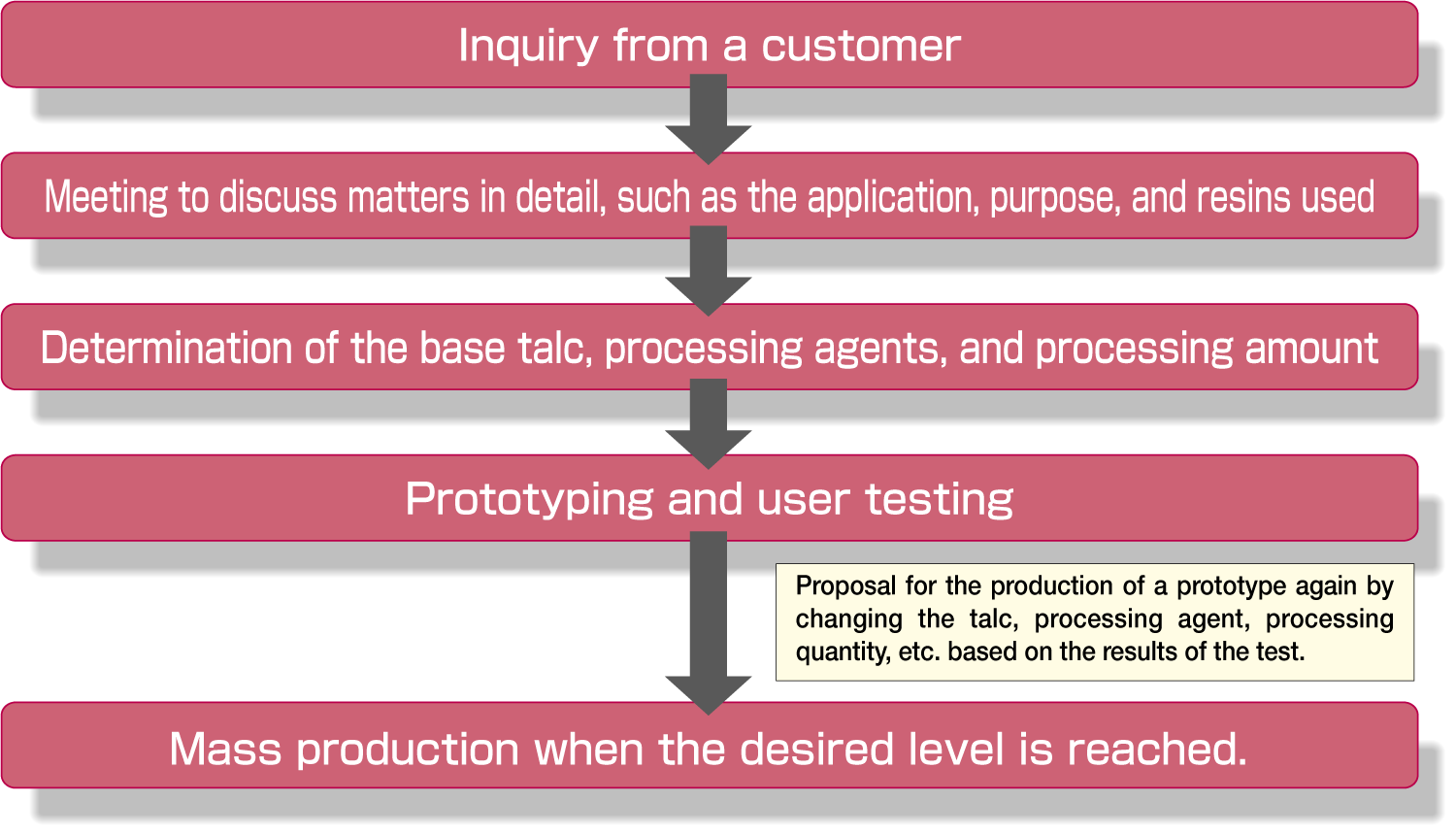

Surface treated Talc

The resin affinity, dispersibility, and water repellency of talc can be improved by chemically and physically coupling the surface of talc with a chemical treating agent, such as a silane.

Nippon Talc applies surface treatment know-how developed in house to in-house equipment and conduct manufacturing activities, ranging from the small-scale production of prototypes to the mass production of products.

Various types of talc are available for bases, such as NANO ACE , ultrafine-powder talc, fine-power talc, general-purpose talc, and burnt talc. Furthermore, treatment agents in a wide range, such as epoxy, amino-based, silicon-based, and fatty acid-based agents, are available.

Nippon Talc applies surface treatment know-how developed in house to in-house equipment and conduct manufacturing activities, ranging from the small-scale production of prototypes to the mass production of products.

Various types of talc are available for bases, such as NANO ACE , ultrafine-powder talc, fine-power talc, general-purpose talc, and burnt talc. Furthermore, treatment agents in a wide range, such as epoxy, amino-based, silicon-based, and fatty acid-based agents, are available.

Water repellency comparison

before and after treatment