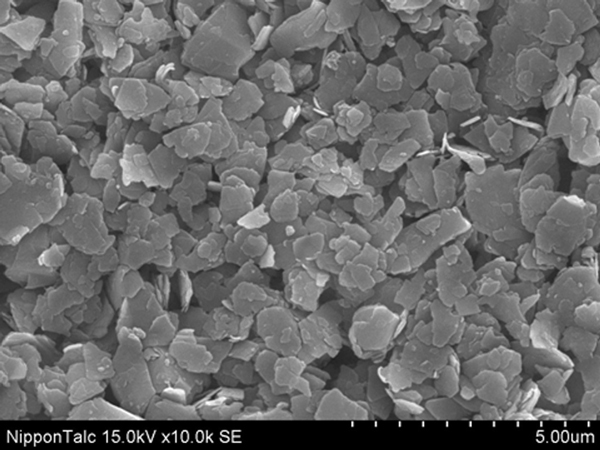

Conventional technology cannot fully bring out the functions of talc, because talc loses its plate-like particle shape when it is atomized.

NANO ACE has been developed as a result of the integration of Nippon Talc’s innovative technology development capabilities.

NANO ACE still maintains the original plate-like particle shape of talc and maximum particle size is properly controlled in the limited range.

NANO ACE attracts attention as it offers new possibilities of talc, such as an expansion of applications to the cutting-edge electronic material field.

NANO ACE applications include resin fillers, crystal nucleating agents, electronic materials, and high value-added adhesive.

NANO ACE D600

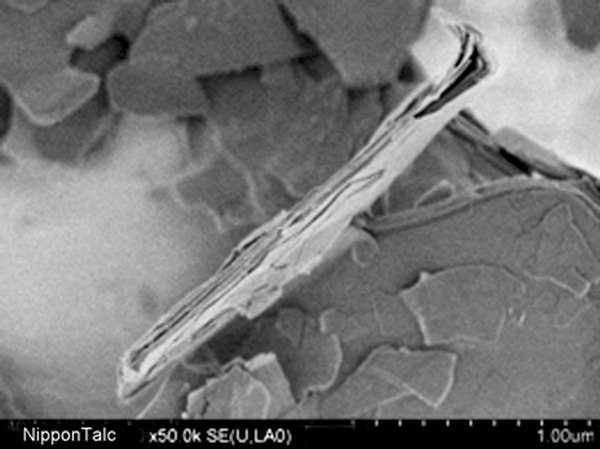

NANO ACE cross-sectional photograph(50,000 times)

| Product | Test Item | |||||

|---|---|---|---|---|---|---|

| Whiteness(%) Reflectance method |

Particle size D50(μm) Laser diffraction |

TOP size(μm) Laser diffraction |

Moisture content(%) JIS K 5101 |

Apparent density(g/ml) JIS K 5101 |

Specific surface area(㎡/g) BET method |

|

| NANO ACE D-600 | 96 | 0.6 | 3.0 | 0.7 | 0.09 | 24 |

| NANO ACE D-800 | 96 | 0.8 | 4.0 | 0.6 | 0.09 | 21 |

| NANO ACE D-1000 | 96 | 1.0 | 4.0 | 0.5 | 0.10 | 20 |

| FG-15 | 96 | 1.5 | 5.0 | 0.5 | 0.10 | 18 |

We have started selling Nano Ace in masterbatch form.

PLA-based: D-600, D-800, FG-15, SG-200N15 All of these are 70% PLA/30% talc

PE-based: D-600 70% PE/30% talc

We can also produce MBs for other products. If you would like a trial sample, please contact us.

The benefits of MB production are improved talc dispersion during compounding, no dust, and reduced effort for the customer in compounding.